Butler Street Foundry

Here is another place I like to hang around, in Bridgeport. A Steampunk contraptionist often finds oneself in need of various metal goods cast, cut, forged, or punched. For this I go to the Butler Street Foundry.Butler Street Foundry was established in 1891. After WWII, iron pouring was ceased due to new environmental regulations and the foundry turned to ironworking. A few years back the third-generation owner retired and sold the business to a man who had been blacksmithing there for 10 years. The new owner opened up the sealed pattern shop and we have been restoring the old machinery and setting the shop back up. Local art students come and cast aluminum and brass, while the owner is trying to bring this 120 year old business into the artistic/restoration/renovation scene. The coal-fired forge is used to do custom iron when the work can be found. The owner is very interested in preserving vintage metalworking methods, however, it is very hard to find anyone under 50 who is into this stuff. My role here is thus that of an apprentice, learning everything I possibly can.

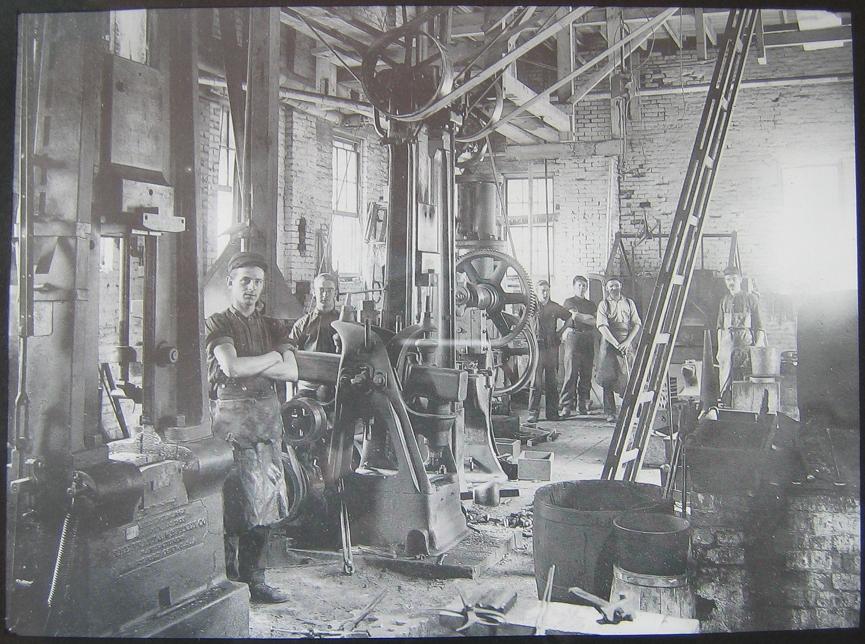

Here is the main floor, where 50-ft beams are broken. Never has the difference between mass and weight been so apparent than when a giant i-beam is swinging from the overhead crane, weightless but not massless.

Originally all power tools were fed via flatbelt from overhead, with a central steam engine providing the power. Now only these few pulleys remain as a reminder of how fortunate we are to have outlets everywhere.

The Blacksmith's Shop

While I enjoy watching pours, my own interest is in the area of blacksmithing.

Flatbelt Triphammers

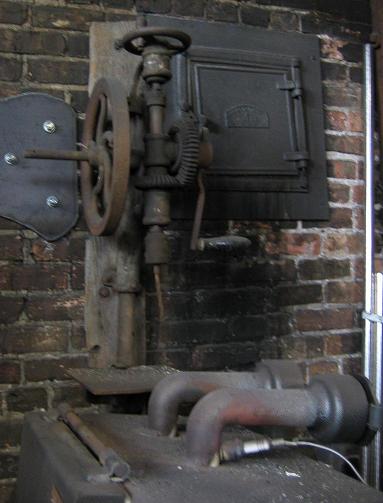

Butler still uses three of its original triphammers, all Little Giants. As you can see they have been converted to electricity:

25lbs

50lbs

100lbs- a real floorshaker

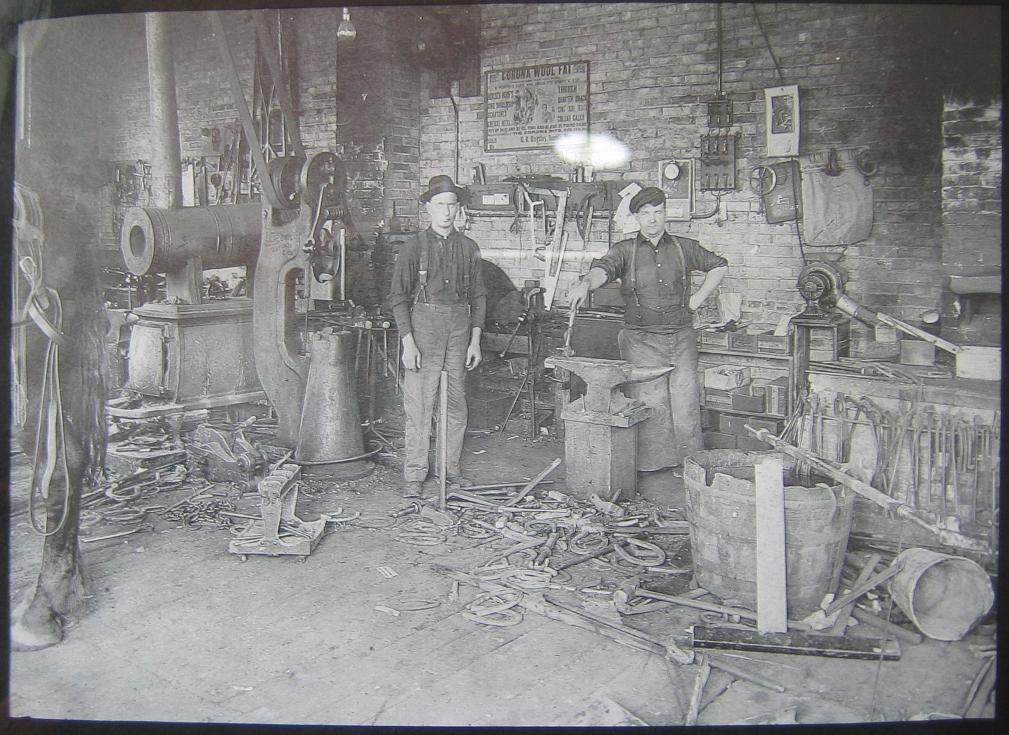

Here you can see the very same tools in use back in the day. Check out the overhead belts and the fact that a horse is patiently awaiting its shoes.

See a video of the 50-lb in use. Watch your fingers!

http://www.youtube.com/watch?v=qe-rIpx8W3Y

Here are some very fine handmade tools, approximately 100 years old. The craftsmanship is incredible.

The Pattern Shop

The foundry used to employ woodworkers to make the original boiler parts and gears that would then be cast in steel. Some of the woodworking here is incredible. The walls are stacked with these wooden originals- flues, manholes, pulleys, gears, flagpole bases, pretty much anything needed. I've even found the originals for parts they cast for their own machinery, still in use out on the floor. What a lost art!

Wow, the old night watchman's clock! He would have had to use keys hanging around the property to prove he made his rounds, and his supervisor would retrieve a little punched slip of paper from within the clock.

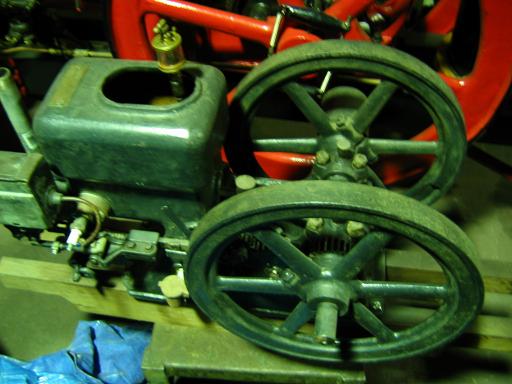

Gas Hit-n-miss Engines

A hit-n-miss is a wonderful engine. It only has one piston, and that piston only fires when it needs to. So rather than the chugachuga of a four-cylinder engine, its one piston is fired when the flywheel slows to a certain speed and you just hear a POPF! now and then. These are gasoline fueled, and some hit'n'misses even used mason jars as fuel tanks. They provide power via a flatbelt PTO.

Hit'n'miss sawmill:

A smaller stationary engine:

Here you see the centrifugal clutch. The spinning motion keeps the little fobs extended. When the speed slows and the fobs drop, the piston (at right) is fired.

Butler Street is a wonderful part of Chicago industrial history!

Visit it!

View Larger Map

The Steampunk World

The Steampunk World

0 Comments:

Post a Comment

<< Home